What is an axle load?

In the complicated world of vehicle compliance, understanding the nuances of axle load is not just a mere technicality but a crucial element that can make or break the efficiency, safety, and legality of commercial vehicles. In its essence, refers to the total weight supported by each axle of a vehicle, a factor often overlooked in the broader discourse of automotive compliance. However, delving deeper reveals a hidden realm of optimisation potential, where manufacturers, bodybuilders, and modifiers hold the reins to unlock enhanced performance and legal adherence.

Beyond the conventional discussions surrounding vehicle compliance, a deeper exploration of axle loads unveils a realm of untapped potential and optimisation strategies. By comprehensively grasping the dynamics, stakeholders in the automotive industry can not only ensure legal compliance but also maximise payload capacity, optimise vehicle performance, and minimise operational costs. This article seeks to shed light on the often-underappreciated significance of axle loads and empower industry professionals with the knowledge needed to navigate the intricate landscape of vehicle compliance in Australia.

Understanding Axle Load Regulations

Legal Limits and Regulations in Australia

Navigating the labyrinth of axle load regulations in Australia requires a nuanced understanding of both federal and state-level mandates. While the overarching aim is to ensure road safety and infrastructure preservation, the specifics can vary significantly, presenting a challenge. Moreover, the dynamic nature of these regulations, subject to periodic updates and amendments, demands a vigilant approach to compliance.

Australia’s axle load regulations extend beyond mere total weight limits, encompassing factors such as axle spacing, distribution, and maximum axle load configurations. For instance, the Heavy Vehicle National Law (HVNL) sets out comprehensive guidelines for axle load limits, axle groupings, and axle spacing, with deviations potentially resulting in hefty fines and legal penalties. Additionally, state-specific regulations, such as those outlined by VicRoads in Victoria, further delineate requirements, underscoring the need for localised compliance awareness.

OEM Ratings and Recommendations

While statutory regulations provide a baseline for compliance, OEM ratings and recommendations offer valuable insights tailored to specific vehicle models and configurations. OEMs invest extensive research and testing into determining optimal axle loads, considering factors like vehicle design, structural integrity, and performance characteristics. As such, adhering to OEM guidelines not only ensures legal compliance but also safeguards against premature wear, structural damage, and compromised vehicle safety.

By meticulously aligning with both regulatory mandates and OEM specifications, manufacturers, bodybuilders, and modifiers can navigate the intricate terrain of compliance with confidence and precision. Embracing a holistic approach that integrates legal requirements with industry best practices empowers stakeholders to optimise vehicle performance, mitigate risks, and uphold the highest standards of safety and regulatory compliance.

Factors Influencing Axle Load

Understanding the complex interplay of factors that influence axle load is essential for those seeking to optimise vehicle performance while ensuring compliance with regulatory standards. Several key variables contribute to axle load dynamics, each requiring careful consideration and strategic planning.

A. Vehicle Design and Configuration

- Vehicle Weight Distribution: How weight is distributed across the vehicle, including factors such as chassis design, engine placement, and payload positioning, significantly impacts axle load.

- Wheelbase Length: The distance between the front and rear axles affects load distribution, with longer wheelbases often resulting in more evenly distributed loads.

- Suspension System: The type and configuration of the suspension system play a crucial role in managing axle load, influencing factors such as ride comfort, stability, and load-bearing capacity.

B. Payload and Cargo Considerations

- Payload Weight: The weight of the cargo or payload being transported directly impacts axle loads, necessitating careful assessment and optimisation to prevent overloading.

- Cargo Distribution: How the cargo is distributed within the vehicle, including its position relative to the axles and its impact on weight distribution is critical for maintaining balanced axle loads.

- Dynamic Load Variations: Factors such as acceleration, deceleration, and cornering can induce dynamic load variations, requiring allowances to be made for potential changes in axle load during operation.

By proactively addressing these factors and implementing strategic measures to optimise axle load distribution, stakeholders can achieve not only regulatory compliance but also enhanced vehicle performance, operational efficiency, and safety. A holistic approach that integrates vehicle design considerations with payload management strategies empowers industry professionals to navigate the complexities of axle load dynamics with confidence and precision.

Consequences of Ignoring Axle Load

Failure to adequately address axle load considerations can have far-reaching consequences. Ignoring axle load requirements not only jeopardises safety but also exposes stakeholders to legal liabilities and operational inefficiencies. Understanding the potential repercussions is paramount for fostering a culture of compliance and accountability within the industry.

A. Safety Risks

- Increased Accident Potential: Overloaded axles compromise vehicle stability and handling, increasing the risk of accidents, particularly during braking, cornering, or sudden manoeuvres.

- Structural Integrity Compromises: Excessive axle loads can lead to premature wear and tear on vehicle components, including tyres, suspension systems, and braking mechanisms, compromising overall structural integrity and safety.

- Road Infrastructure Damage: Overloaded vehicles exert excessive pressure on road surfaces, contributing to premature wear and deterioration of infrastructure, posing safety hazards for other road users.

B. Legal Ramifications

- Regulatory Violations: Non-compliance with axle load regulations can result in fines, penalties, and sanctions imposed by regulatory authorities, tarnishing reputations, and undermining business viability.

- Liability Exposure: In the event of accidents or incidents involving overloaded vehicles, stakeholders may be held liable for damages, injuries, or fatalities, subjecting them to costly legal proceedings and financial liabilities.

- Operational Disruptions: Legal disputes and regulatory non-compliance can disrupt operations, leading to downtime, loss of productivity, and damage to customer relationships and brand reputation.

By recognizing and addressing the potential consequences of ignoring requirements, industry professionals can prioritise compliance efforts, mitigate risks, and uphold the highest standards of safety, legality, and operational excellence. Proactive measures, such as implementing robust compliance protocols and investing in employee training and education, are essential for safeguarding against the adverse effects of non-compliance in the dynamic automotive landscape.

Strategies for Managing Axle Loads

Effectively managing axle loads is a multifaceted endeavour that requires a combination of strategic planning, technical expertise, and adherence to regulatory standards. Manufacturers, bodybuilders, and modifiers can leverage various strategies to optimise axle load distribution, enhance vehicle performance, and ensure compliance with legal limits.

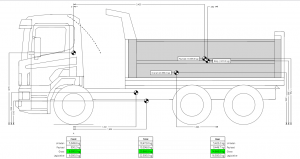

Axle Load Calculations

- Utilising Advanced Tools and Techniques: Employing axle load calculation methodologies, enables stakeholders to precisely determine optimal load distributions and configurations.

- Maximising Legal Limits: By leveraging axle load calculations, industry professionals can identify opportunities to maximise vehicle payload within legal limits, optimising operational efficiency and profitability.

- Ensuring Compliance and Safety: Rigorous axle load calculations help prevent overloading of axles, safeguarding against safety hazards, structural damage, and regulatory violations.

- Collaboration with Compliance Experts: Collaborating with compliance specialists, such as Commercial Vehicle Compliance, can provide invaluable insights and support in conducting axle load calculations and ensuring regulatory compliance.

Vehicle Modification Approvals

- Seeking Engineering Certifications: Obtaining engineers’ certificates or VASS certificates for vehicle modifications. It is better to involved a compliance experts in the build while in design stage and had some inputs to ensures that axle load distribution meet regulatory requirements and industry standards.

- Prioritizing Payload Optimisation: Integrating axle load considerations into vehicle modification processes allows for the optimisation of payload capacity, enhancing operational efficiency and cost-effectiveness.

- Implementing Proactive Compliance Measures: Proactively addressing axle load requirements during vehicle modifications mitigates the risk of non-compliance and associated legal, financial, and reputational consequences.

By embracing strategic approaches to managing axle loads, industry stakeholders can navigate the complexities of vehicle compliance with confidence and precision. Leveraging axle load calculations, compliance expertise, and proactive modification approvals empowers professionals to optimise vehicle performance, maximise payload capacity, and uphold the highest standards of safety and regulatory adherence.

Conclusion

In conclusion, axle load management stands as a critical pillar of vehicle compliance, demanding meticulous attention and strategic planning from manufacturers, bodybuilders, and modifiers in the automotive industry. By understanding the complexities of axle load dynamics, stakeholders can unlock opportunities to optimise vehicle performance, enhance safety, and ensure adherence to regulatory standards.

Throughout this article, we’ve explored the multifaceted nature of axle load considerations, ranging from legal regulations and OEM recommendations to the consequences of non-compliance and strategies for effective management. From the intricate nuances of vehicle design and payload distribution to the potential safety risks and legal ramifications of overlooking the requirements, the importance of comprehensive compliance measures cannot be overstated.

As industry professionals navigate the ever-evolving landscape of automotive compliance in Australia, embracing proactive approaches to management becomes imperative. By leveraging advanced tools, seeking collaboration with compliance experts, and prioritising payload optimisation, stakeholders can position themselves for success in an increasingly competitive and regulated environment.

For comprehensive axle load calculations reports, modification approvals, and compliance support, Commercial Vehicle Compliance (CVC) stands ready to assist. With our expertise and dedication to excellence, we empower industry professionals to achieve maximum payload capacity, ensure regulatory compliance, and optimise operational efficiency. Contact us today to learn more about how CVC can support your compliance needs and propel your business forward.

One Reply to “What is an axle load?”

What’s Happening i am new to this, I stumbled upon this I have discovered It absolutely helpful and it has aided me out loads.

I hope to give a contribution & help different customers like its aided me.

Good job.