Due to the many different sizes available of both vehicles and wheelchairs, along with their occupants, the taxi requirements are designed to accommodate majority of the circumstances. Private users and vehicles can be designed to suit the needs of individuals based on the size of the wheelchair in used and the occupant.

This content will provide you an overview of the different requirements regarding the installation of wheelchair loaders and restraint systems used, the transportation of wheelchairs and their occupants in motor vehicles. The details below are mainly for the use of wheelchairs in taxis.

General

An approved certificate supplied by an engineer who is a signatory to the Vehicle Assessment Signatory Scheme (VASS) regulated by VicRoads, must be presented to show that a modified WAT has met the relevant standards for registration. The approved certificate must be presented if modifications are performed that could unfavourably affect the structural integrity of the vehicle, such as major body or chassis modifications; the vehicle’s handling features; any primary security system, such as steering system modifications; or modifications performed that affect the vehicle’s compliance with the standards for registration. Also, it is needed if seats are added or removed and seat belts are mandatory for the added or remaining seats; or child restraint anchorages are installed to the vehicle.

Child restraint anchorages must be available for use for at least two (2) forward facing rear seating positions. Anchorages must conform with applicable ADRs.

A fully functional fire extinguisher of at least a 20B rating must be securely mounted in the Wheelchair Accessible Taxicab (WAT) and must be available for use always.

All equipment related to the operation of the Wheelchair Accessible Taxicab (WAT) must be kept in good working order.

Allocated Floor Space / Access

There are mandated laws that require you to comply with. For instance, a wheelchair position in a Wheelchair Accessible Taxicab – WAT (allocated floor/ceiling space) must have an allocation of at least 1300 mm (length) x 800 mm (width) x 1500 mm (height). All Wheelchair Accessible Taxicabs (WATs) must have a door entry measurement (i.e. where wheelchairs enter) of at least 1500 mm high and 800 mm wide. These are all stated by the Commonwealth Government’s Disability Standards for Accessible Public Transport.

Accreditation Partners

Wheelchair/Occupant Restraint Systems

• Occupant restraint system (seat belts) and wheelchair restraint system are the two restraint systems that are required.

• Seat belts must be a lap & harness type assembly or lap & sash emergency locking retractor type.

Note: A lap only seat belt is a non-compliant restraint system for people in wheelchairs.

• Wheelchairs must be fastened securely using restraints (can be up to four tie-down points) to the WAT. Quantity sets of restraints and wheelchair positions must be proportional to each other.

• Wheelchair restraints must be in good order, free from being frayed, worn, and torn.

• All restraints installed must comply with the applicable Australian/New Zealand standards which includes AS/NZS 10542 Parts 1 & 2 Wheelchair tiedown and occupant-restraint systems and any requirements included in AS2942 – 1994/Amendment 1-1998 Wheelchair Occupant Restraint Assemblies for Motor Vehicles’ that are not included in AS/NZS 10542 Parts 1 & 2.

Hoist and Ramps

Hoists installed to WATs must be strongly mounted to the vehicle; have a skid resistant loading surface; have approach edges with an outer roll stop that is effectual when the hoist is elevated off the ground; and not have a vertical distance more than 12 mm between the horizontal surface of the hoist platform, in its fully elevated position and the horizontal surface of the vehicle entrance. (i.e. at floor level).

A gradient/slope no steeper than one in six (1 in 6) and a width of not less than 800 mm is required in all ramp installed to a WAT licensed. Any WAT approved prior to 28 September 2015 with a one in four (1 in 4) gradient ramp is not subject to this requirement.

Hoists and ramps must comply with the applicable Australian/New Zealand Standards, including AS 3856 – Hoists and Ramps for people with disabilities – Vehicle mounted; Parts 1 and 2.

MODIFICATION CODE R2

Wheelchair Loader Installation

- Installation of a wheelchair loader intended for automotive use and manufacturing & installation of an automotive type door are the modifications that are incorporated under this code.

- Installation of wheelchair loaders that is not intended for automotive use and installation of vehicular wheelchair restraints. Are the modifications that are NOT incorporated under this code.

NOTE: The modified vehicle must continue to comply with all applicable ADR’s, Australian Standards, and Regulations/Acts.

MODIFICATION CODE K5

Installation of Wheelchair Occupant Restraint System

- Fitting of wheelchair occupant restraint assemblies and anchorages that complies with Australian/New Zealand standards AS/NZS 10542.1:2009 Technical systems and aids for disabled or handicapped persons are the modifications that are incorporated under this code.

- Fitting of non-approved wheelchair restraint systems and fitting of seats or seat belt assemblies and their anchorages are the modifications that are NOT incorporated under this code.

NOTE: The modified vehicle must continue to comply with all applicable ADR’s, Australian Standards, and Regulations/Acts.

Specific Requirements

1.0 Restraint Requirements

1.1 Restraint Design and Construction

The section/s relating to “Design, Construction and Testing” of Australian/New Zealand standards AS/NZS 10542.1:2009 Technical systems and aids for disabled or handicapped persons, must be followed in designing, constructing, and installing the wheelchair restraints and wheelchair occupant restraints.

1.2 Restraint Marking and Packaging

There must be evidence to show that the wheelchair occupant restraint assemblies and subassemblies fitted are/were marked and packed in accordance with the section/s relating to “Marking and Packaging” of AS/NZS 10542.1:2009.

1.3 Restraint Assembly and Installation

The manufacturer’s instructions provided in accordance with the section/s relating to “Instructions for Installation” of AS/NZS 10542.1:2009 must be observed in installing the wheelchair restraint and wheelchair occupant restraint systems.

1.4 Restraint System Location

The clause/s relating to ”Clear space Requirements” of AS/NZS 10542.1:2009 must be observed in installing the wheelchair restraint and wheelchair occupant restraint systems to satisfy the restraint system manufacturer’s clear space requirements.

When not in used by a wheelchair, the area where the wheelchair(s) is restrained must not be used as a baggage area.

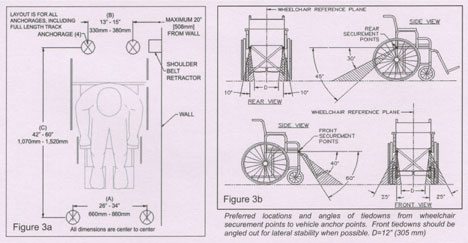

1.5 Restraint Anchorages

1.5.1 The guidelines for vehicle strengthening in AS/NZS 10542.1:2009 should be observed. Wheelchair and occupant restraint anchorage points must be strong enough to endure all anticipations of loading. The vehicle usually needs strengthening at the mounting points, and the type of strengthening needed will depend on the applied loads and the strength of the vehicle structure near the anchorages.

1.5.2 Supporting plates must be extended and fully soldered to the nearest body bearer or cross member of the vehicle in cases where timber floors are used.

1.5.3 High tensile bolts which fully engage the threads of the nuts must be used in every wheelchair and occupant restraint anchorage points for strengthening. In addition, self-locking or captive type nuts must also be used.

1.5.4 The position of the occupant restraint anchorages must comply with the requirements given in clause/s relating to “Occupant Restraints – Anchorages or Anchor fittings” of AS/NZS 10542.1:2009.

2.0 Vehicles Used for Transport of Wheelchair Occupants

2.1 Vehicles which are used to carry different kinds of wheelchairs or more than one wheelchair is recommended to follow minimum dimensional requirements (based on the wheelchair dimensions and clearance zones outlined in AS/NZS 10542.1:2009):

2.1.1 A minimum 800mm width of doorways for wheelchair access

2.1.2 A minimum 1400mm height of doorways for wheelchair access

2.1.3 A minimum of 1500mm for internal headroom

2.2 It is better for vehicle windows to extend up to minimum 1400mm height from the vehicle floor so that wheelchair occupants will have a clearer view of surroundings.

2.3 The above minimum dimensional requirements should be met if the vehicle to be modified is to be used as a hire and reward vehicle (i.e. a taxi). Check with the specific registering authority for any special requirements.

2.4 Vehicles which are used to carry different kinds of wheelchairs or more than one wheelchair must meet the emergency exit requirements by fulfilling the following requirements:

• Installation of wheelchair should not block any emergency exits in any of its states-occupied or otherwise.

• Means of emergency exits should remain free of barriers and be able to be opened outwards from both inside and outside.

• Means of emergency exit should be identified by a visible and prominent notice inside and outside the vehicle, displaying the words “EMERGENCY EXIT”, and by words and/or symbols signifying how it is opened, unless, by the exit design, the way of opening is understandable.

2.5 It is recommended to contact the Taxi Licensing Section of the relevant State authority to determine any unique requirements before starting the modifications for Hire and Reward vehicles.

Recommended layout positions of anchorages.

References:

• Victoria Government Gazette No. S 235 Friday 29 July 2016 By Authority of Victorian Government Printer – Transport (Compliance and Miscellaneous) Act 1983

• Government of Western Australia Department for Planning and Infrastructure

• VSB 6 – Heavy Vehicle Modifications Appendix 2 – Modification Code R2 – Wheelchair Loader Installation

• VSB 6 – Heavy Vehicle Modifications Appendix 5 – Modification Code K5 – Installation of Wheelchair Occupant Restraint System